Georg Hagelschuer

Die Herausforderung

Dampf- und Heißwasserkesselanlagen gehören nach der Betriebssicherheitsverordnung zu den überwachungsbedürftigen Anlagen. Alle wichtigen, zu ermittelnden technischen Werte und Parameter mussten bisher handschriftlich eingetragen werden.

Wenn man sich vor Augen führt, dass 80 % der verarbeitenden Industrie für thermische Produktionsprozesse Dampf benötigt, wird deutlich, wie elementar ein zuverlässiger und planbarer Anlagenbetrieb für die Kunden von Hagelschuer ist. Der Ausfall der Prozessdampfversorgung hat zur Folge, dass die gesamte Produktion still liegt. Hagelschuer hat es sich zum Ziel gesetzt, die komplexen Zusammenhänge aller Betriebsparameter der Dampf- und Heißwasserkesselanlagen zu digitalisieren und gleichzeitig zu analysieren, um automatisch Handlungsempfehlungen daraus abzuleiten. Dadurch kann ein sichererer und effizienterer Betrieb der Anlagen dauerhaft gewährleistet werden. Die Erfassung, Analyse und Auswertung der Daten sollte eine webbasierte App Lösung sicherstellen.

Überwachung und Dokumentation von Dampf- und Heißwasser Kesselanlagen

Bislang musste das Kesselbuch für Dampf- und Heißwasserkesselanlagen in Papierform geführt werden (Vorschrift für alle Anlagen). Mit der WebApp

gh-focus, die vom TÜV abgenommen wurde, darf dies jetzt in digitaler Form passieren.

oder bei

WA-Podcast – Spotify – iTunes – Youtube

Die Zielsetzung

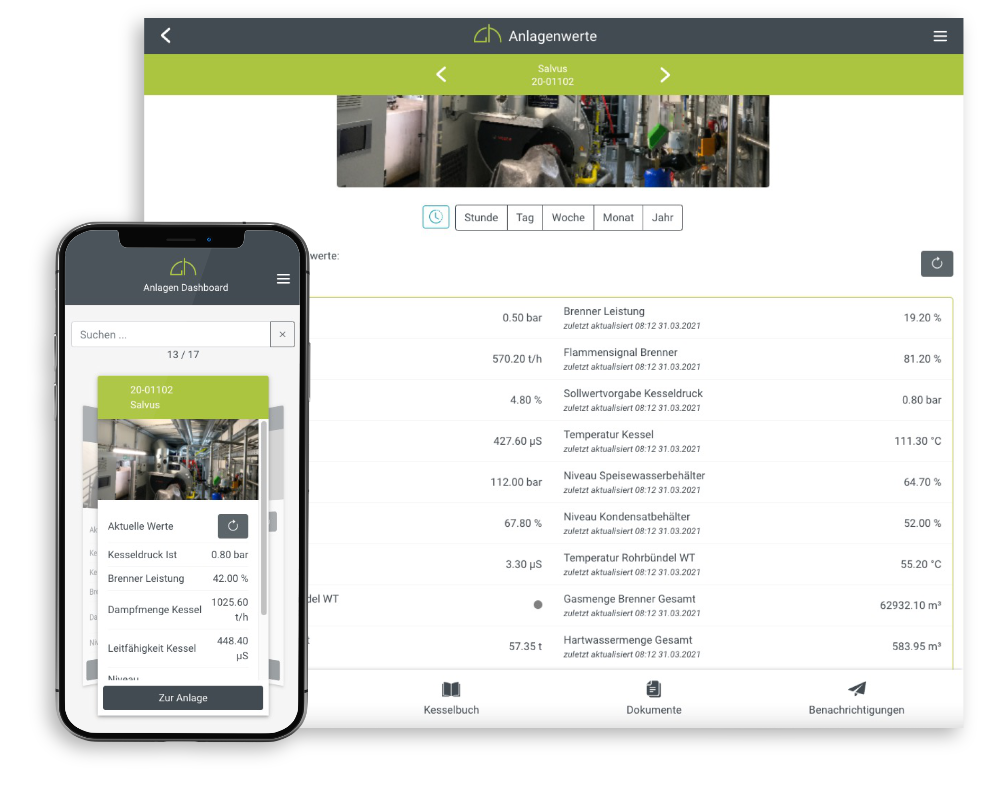

Die Entwicklung einer WebApp mit dem Namen gh-focus. Die Anwendung sollte nach dem „Mobile first“ Ansatz auf allen Endgeräten funktionieren, sowie intuitiv und einfach zu bedienen sein.

Einfache Bedienbarkeit auf allen Endgeräten

Alle mit der Beaufsichtigung der Anlage beauftragten Personen, sowie die Kolleginnen und Kollegen aus der Verwaltung, sollten gleichermaßen in der Lage sein die App zu nutzen.

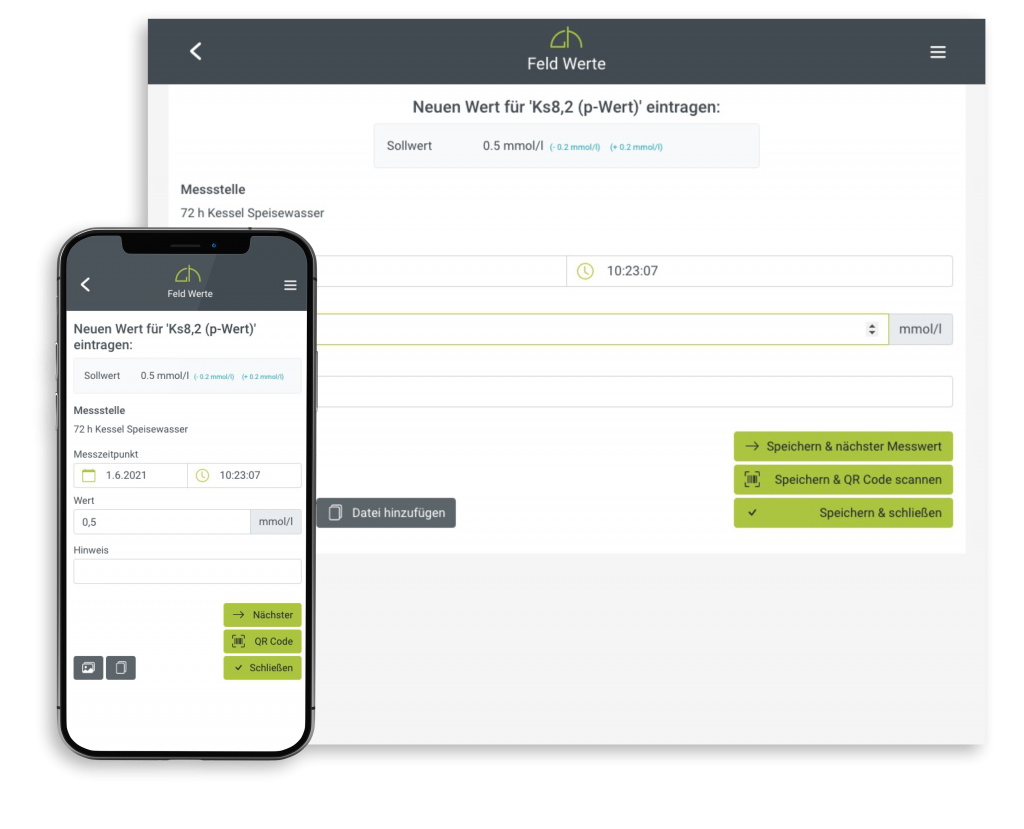

Schnelles Erfassen der Werte durch QR-Codes

Die an der Anlage zu ermittelnden technischen Werte, wie z.B. die tägliche Entnahme des Kesselspeisewassers, erfolgt über den Probeentnahmekühler. Über einen QR-Code, der am Probeentnahmekühler, sowie an allen weiteren relevanten Messstellen der Anlage angebracht ist, sollte der Nutzer direkt per Scan zu der jeweiligen Messstelle in der WebApp gelangen. Dort kann dann der ermittelte Wert einfach eingegeben und gespeichert werden. Außerdem sollte es möglich sein, Bilder und Begleitdokumentationen zu einer Messung zu dokumentieren.

Automatische Parameterüberwachung

Darüber hinaus sollte die App automatisch alle technischen Werte und Parameter mit den hinterlegten Sollwerten abgleichen und direkt eine Warnung ausgeben, wenn Abweichungen bestehen. Für diese automatisch generierten Warnungen sollte für alle Nutzer eine nachvollziehbare Meldekette (SMS & E-Mail) ersichtlich werden, um eine größtmögliche Betriebssicherheit und optimale Prozessabläufe hinsichtlich des Anlagenbetriebs zu garantieren.

Verwaltung von Anlagendokumenten

Das System sollte durch eine digitale Anlagenakte, in der alle Dokumente, Fotos und Reports chronologisch zur Verfügung stehen, abgerundet werden.

Analyse durch Konzeptions-Workshop

Um eine praxistaugliche, benutzerorientierte Lösung zu entwickeln, war es uns sehr wichtig vorab die Zielgruppen genau kennenzulernen. Daher wurde in einem Konzeptions-Workshop, den wir unseren Kunden vor jeder Projektumsetzung empfehlen, die Zielgruppe für die gh-focus Plattform erarbeitet.

Workshop Anforderungen

- Intuitive Bedienung und klar strukturierte Darstellungsweise

- Optimale Darstellungsweise auf allen gängigen Endgeräten

- Ansprechendes modernes Design (erarbeitet im Design-Workshop)

- Alle Module können später weiterentwickelt werden

Das Ergebnis

Die gh-focus Anwendung wurde von uns als responsive WebApp umgesetzt und kann dadurch problemlos und ortsunabhängig von allen gängigen Endgeräten bedient werden. Über das individuell konfigurierbare Dashboard ist der Anlagenstatus immer direkt einsehbar. Dank eines Farbleitsystems sind abnormale Werte sofort ersichtlich und können somit unverzüglich behoben werden. Die Informationsfelder lassen sich einzeln bearbeiten und erweitern. Neue Messpunkte können jederzeit hinzugefügt und konfiguriert werden. Eine umfassende Suchfunktion ermöglicht die gezielte Suche nach einzelnen Werten. Für eine individuelle Anpassung und Priorisierung sorgt die Gruppierungsfunktion. Mithilfe dieser Funktion lassen sich Messfelder gruppieren und in der gewünschten Reihenfolge anordnen. Die wichtigsten Messwerte können als Favorit markiert werden und sind auf dem Dashboard verfügbar. Automatisch über die Anlagentechnik erfasste Messwerte werden per IoT Maschinenschnittstelle eingepflegt und umgehend angezeigt, dazu gehört auch der Stand der letzten Aktualisierung. Zu Auswertungszwecken können die Messergebnisse als Diagramm und/oder als Tabelle im Verlauf angezeigt und analysiert werden.

Georg Hagelschuer GmbH & Co. KG

Die Georg Hagelschuer GmbH & Co. KG wurde 1991 als reiner Dampfkessel-Servicebetrieb gegründet. Seit 30 Jahren bietet Hagelschuer nun individuelle Komplettlösungen rund um die effiziente Dampfversorgung an und deckt dabei die gesamte Prozesskette ab. Hagelschuer zeichnet sich aus durch bedarfsorientierte Beratung, erstklassiges Engineering, hochwertige Fertigung und exakte Montage bis zur termingerechten Inbetriebnahme. Außerdem bietet Hagelschuer seinen Kunden Dampf- und Heißwasserkesselanlagen zur Miete an. Die Mietenergieanlagen sind europaweit im Einsatz und runden zusammen mit dem umfangreichen Fachhandel und dem Service das Produktportfolio ab. Zu den langjährigen und treuen Kunden gehören Unternehmen aus Lebensmittel-, Industrie-, Wirtschafts- und Dienstleistungsbranchen, Chemieparks und Energieanlagenbetreiber aus Deutschland und der Europäischen Union.